Deleted

Registered: Dec 4, 2024 19:43:39 GMT -7

Posts: 0

|

Post by Deleted on Jan 5, 2014 14:21:38 GMT -7

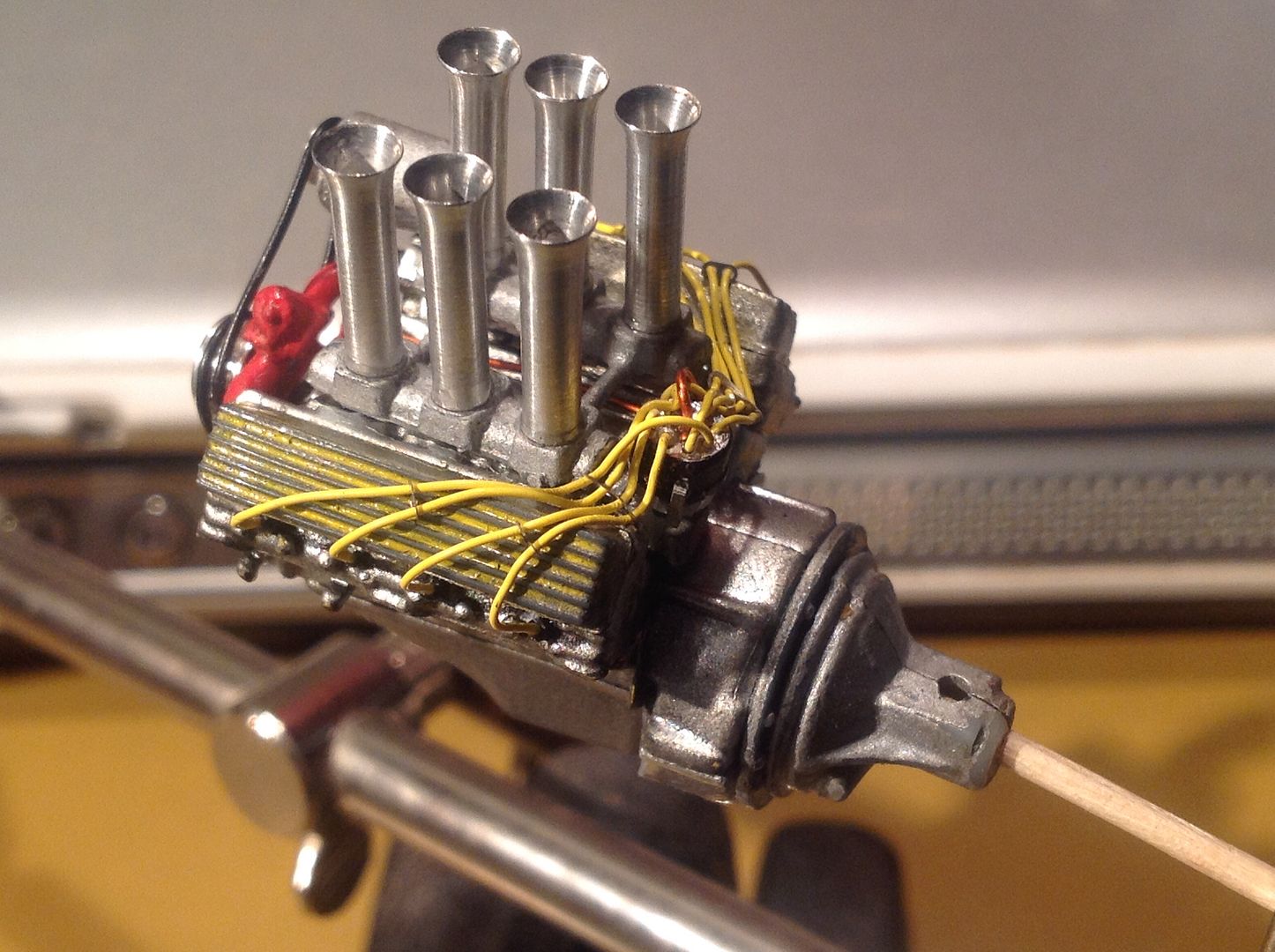

So for my Xmas challenge I have a Nascar, and thought I would try my hand at wire looms. After about 2 hours of trying to get the looms to glue to the engine (including using accelerant), I gave up. How do you guys do wire looms? How do you get them to stick to the engine without getting glue in the holes? Then once its glued in place, how do you get it to stay there when fishing the wire through?

Thanks!

|

|

Deleted

Registered: Dec 4, 2024 19:43:39 GMT -7

Posts: 0

|

Post by Deleted on Jan 5, 2014 16:19:47 GMT -7

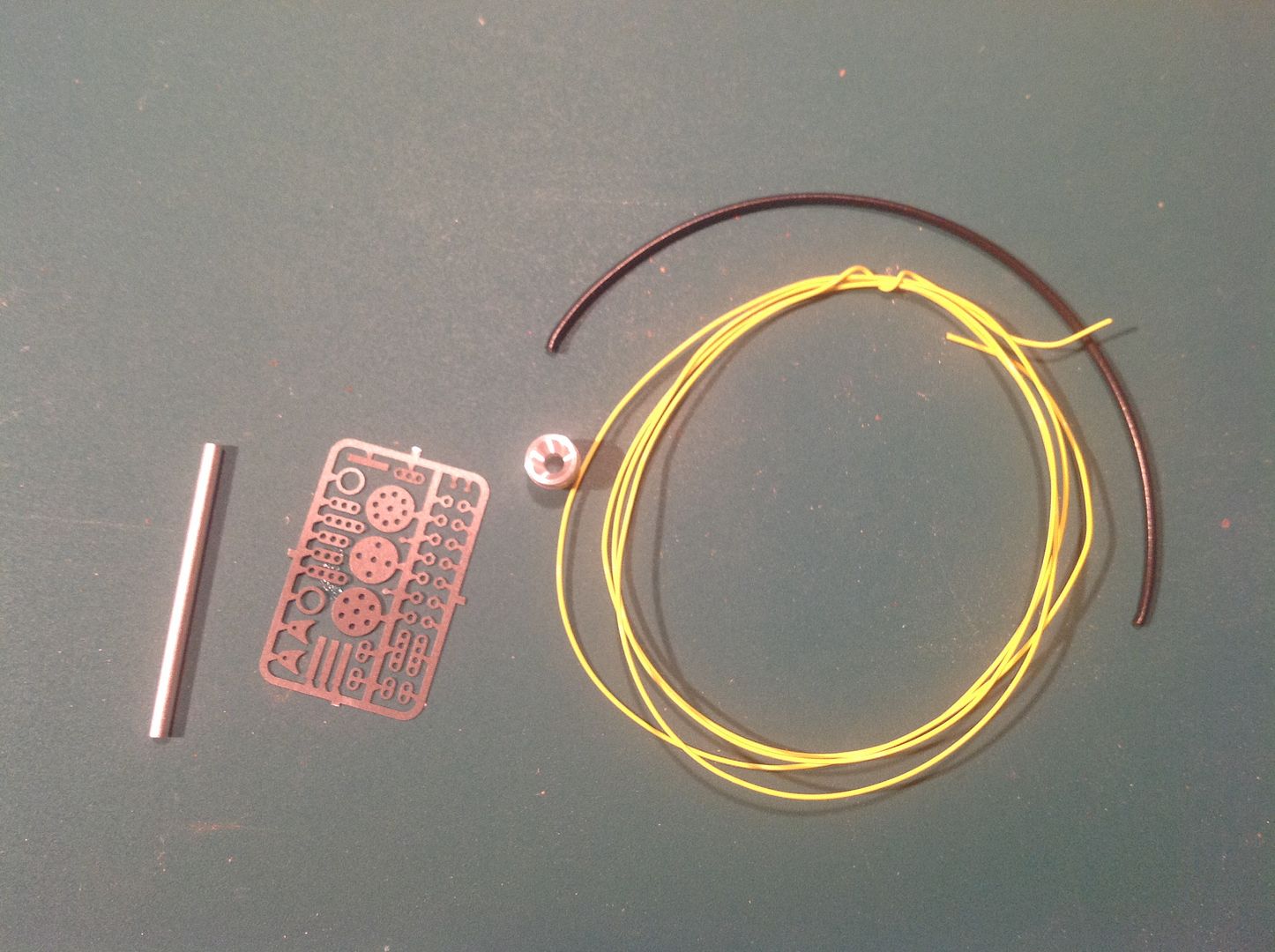

Here's the secret that I use.......no glue. Absolutely no glue at all. This is assuming you are using the looms with the full ring like the ones in the pic. Put the wires through the looms and finish wiring the engine. Careful that one doesn't slip out. I usually bed the wire at the tip in case it slides to the end it catches it. When the glue dries completely on the wire at both ends, you can press the wires down where you want them to be and slide the looms where you want them as well. If you are using looms that are open then you will have to glue those down. I've never used them before for the same reason but I would recommend glue with a toothpick where you want them and then accelerator with a small brush or toothpick as well and just let a very small amount drop on to the glue. Its how I glue small parts. I hope this helps.   |

|