Deleted

Registered: Nov 21, 2024 14:06:30 GMT -7

Posts: 0

|

Post by Deleted on Dec 2, 2013 9:20:17 GMT -7

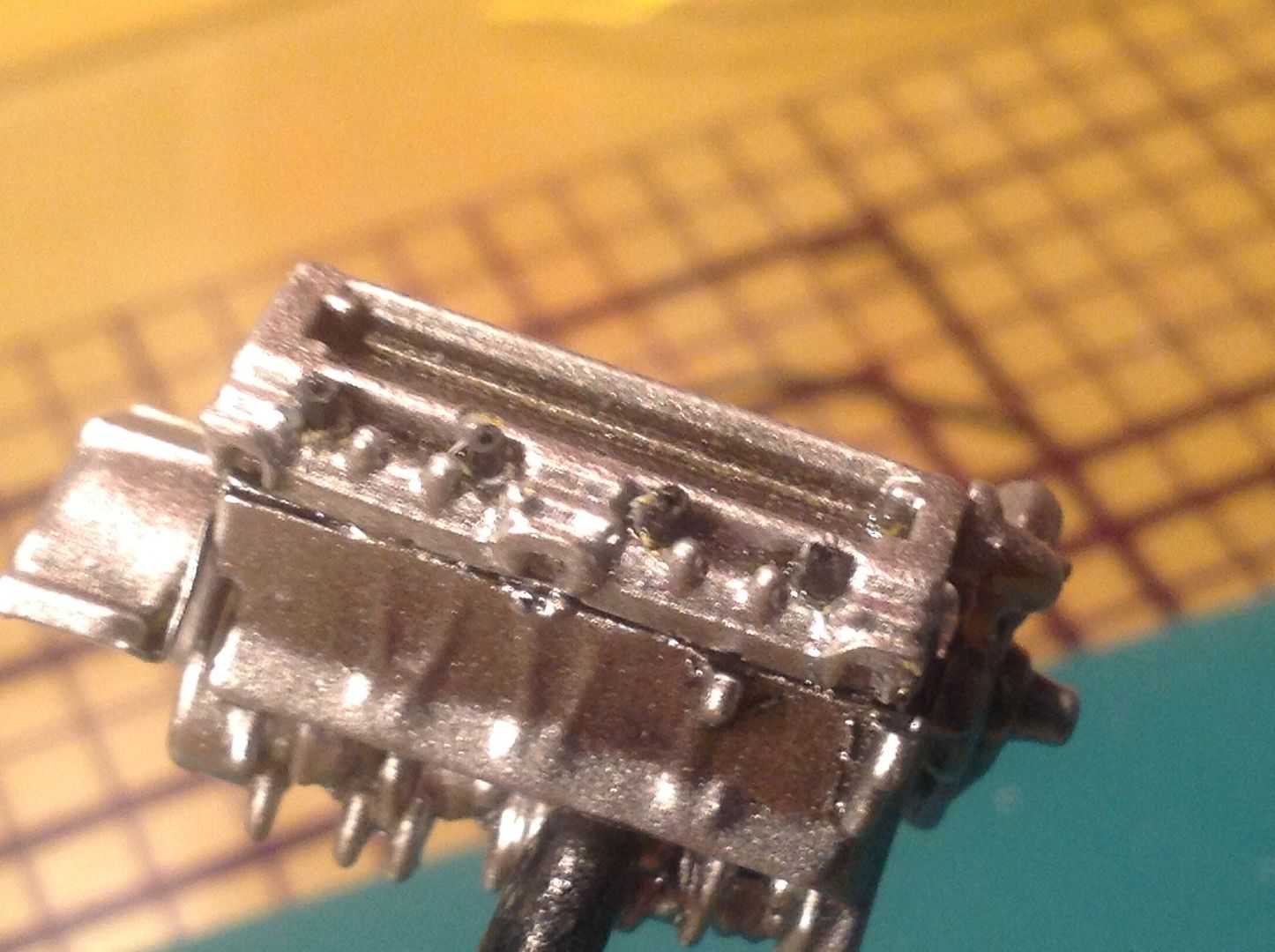

So I had a lot of success buying ignition wire insulators where they attach to the valve cover (or between headers like SBC's) using insulators from Pro Tech, I thought I'd fashion my own. But I wanted them smaller, the dimensions of the wire vs the insulator much closer. I had some leftover rubber covered alum core wire about .021 and used an xacto to roll the wire around until the insulation cut through. After a couple times, I could use needle nose and pull the inner core right out, leaving a hollow tube which fit snugly around the standard .018 vertex mag wire. Tried the 1st time with the coil sliding the insulation on first, then cutting the wire to length and gluing while making sure the insulaton was down at then end of the wire.

Then stupid is as stupid does set in. I cut 8 small pieces and glued them to the valve covers next, intending to slip each wire into the hole after I spec'd out the hemi firing order. Wrongo! The CA got drawn up into the insulation pieces and now I have to glue one at a time, using doctor's clamps (also used as roach clips LOL) to secure one at a time.

So, if you're doing this detail in the future, cut the wires to length, slide the insulators on first BEFORE GLUING! It also wouldn't hurt to dremel a tiny hole for each insulator in the valve cover for added security.

|

|

Deleted

Registered: Nov 21, 2024 14:06:30 GMT -7

Posts: 0

|

Post by Deleted on Dec 2, 2013 9:57:46 GMT -7

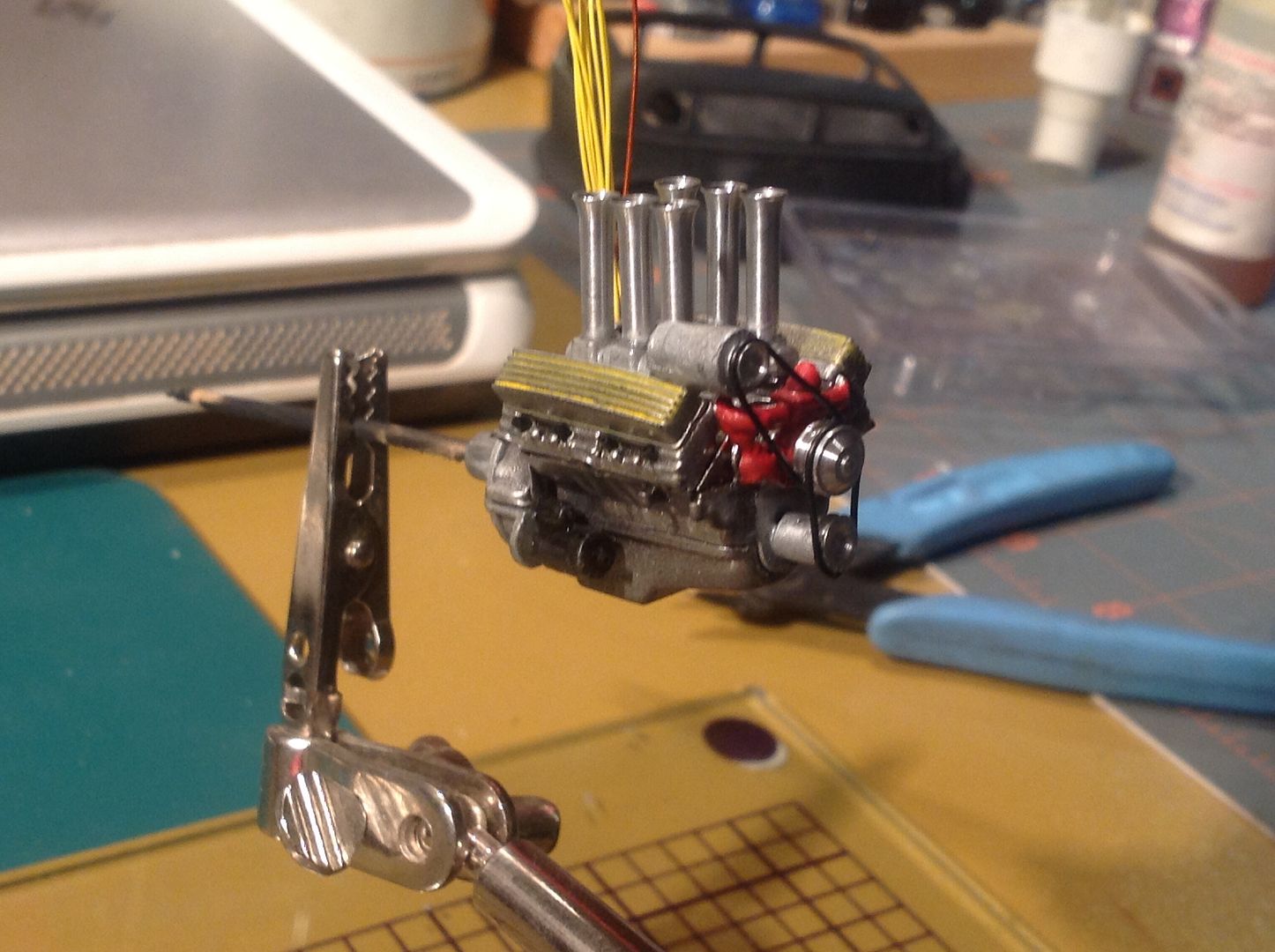

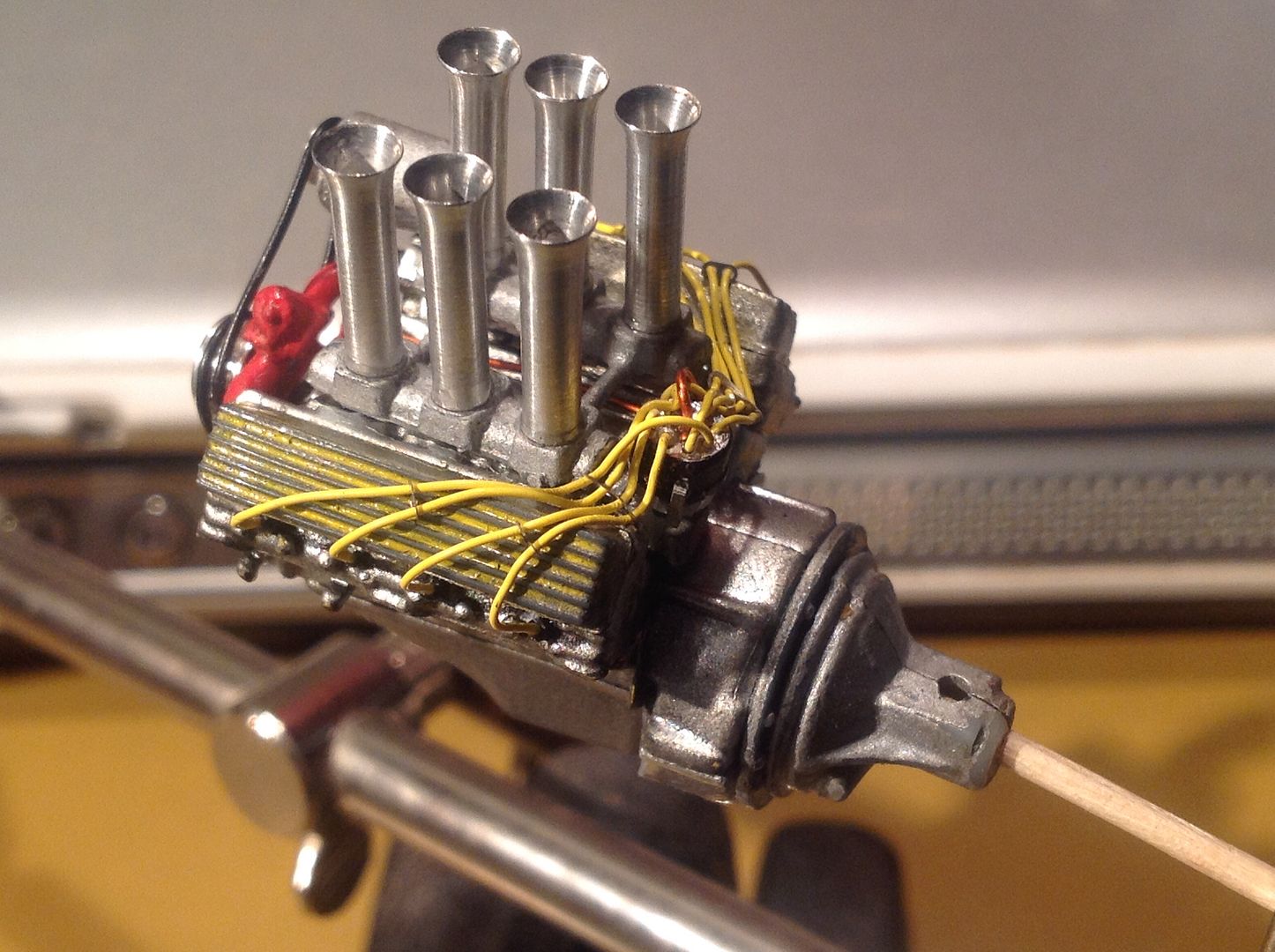

Great tip Mitch. If you drill a hole in the valve cover, you only need but a drop of glue for the insulator/boot. I actually do it that way. To me it's a lot easier to get the length just right without have to worry about the boot sliding off or losing it. Since wiring is one of the last things I do anyways. Best thing about it is that the distributors I use already includes boot material so it's the exact size. Here's an example   Here's what it looks like once it's wired along with looms.  |

|

Deleted

Registered: Nov 21, 2024 14:06:30 GMT -7

Posts: 0

|

Post by Deleted on Dec 5, 2013 7:14:12 GMT -7

that's a dist from detail master, right? Their wire always seems a tad bigger than the M.A.D. I use. I also use Vertex mags, which shafted me (no pun) on my Mustang flopper. It only had 8 wires, which is unusual 'cause I've had some with 9 (one for the MSD or coil). I had to pry the wires aside and fit one in and put a drop of CA in the wire bundle.

I think my touch up helped, but I'll never trust blind luck again! Great engine build Ice!

|

|

|

|

Post by Skip-O-Matic on Dec 5, 2013 20:32:43 GMT -7

Thanks for the tips guys. I have run distributor plug wires before, but never did plug boots. I always just used heavy thread and pushed the thread into the holes I drilled in the spark plug location. I have been wanting to start doing the boots and distributor kits. This info will help me with the learning curve.

|

|

Deleted

Registered: Nov 21, 2024 14:06:30 GMT -7

Posts: 0

|

Post by Deleted on Dec 6, 2013 6:19:05 GMT -7

Skip: Pro Tech has really scale sized boots, for both the distributor side and the plug side. I accidentally bought a set of ten 45deg boots for the distributor side, but they worked for the Boss 429 motor I had. They are cheap for a set so whichever style works for you is good. Ice's is really awesome looking and I believe Detail Master is the maker. I like the Pro Tech since I can choose between straight and 45deg depending on the application. Using Ted's wire the way I did is mult-purpose although perhaps not as authentic.

Ice: I had the cheap, asian cast version of your alligator clamp holders/magnifying glass thing. Since I can't use the glass anymore, I've seen something on Ebay that is 4 flexible rods around 18" in length mounted vertically mounted into a solid wood base with clamps on top which looks like a good way to hold bodies for painting or for holding small parts for painting/gluing. Ever seen one?

|

|

Deleted

Registered: Nov 21, 2024 14:06:30 GMT -7

Posts: 0

|

Post by Deleted on Dec 6, 2013 7:48:08 GMT -7

Aside from the Tamiya stands and alligator clips, I usually build my own with a couple of pieces of wood and wire coat hangers. No way I'll spend on a holed anymore. Coat hangers are easy to bend to shape and are super cheap.

For wiring, if I don't already have it! I'll just use wire from an old box of electrical junk that I have. Phone wire for example will give you a ton of wire.

If I want to use PE details I stick to Detail Master pieces. Pro Tech stuff is ok but money adds up if you buy THEIR wire too. With their distributor, ignition coil, and their wire that puts me at almost $12. That's not counting shipping OR boots. Their pre wired distributor is almost $8 and it's just not realistic looking. Lol. I guess you can tell I'm loyal to Detail Master parts. For about $7 shipped I get a distributor, wires, boots, looms, and left over PE parts. That's not a bad deal at all.

|

|

Deleted

Registered: Nov 21, 2024 14:06:30 GMT -7

Posts: 0

|

Post by Deleted on Dec 7, 2013 11:48:49 GMT -7

You've sold me on trying a DM kit; try doing a search for madmodeling.com for distributors, even dual HEMI racing ones. They come mostly pre-build, you get to pick the color of the body/cap/wires and it's built to have that 9th coil wire. I guess everyone has a favorite!

|

|